Innovative synthetic fuel technology could allow combustion engines to remain viable in a future free of fossil fuels.

What Are E-Fuels?

Electrofuels, or E-fuels, are fuels which utilise the process of electrolysis during their production. They are also commonly referred to as synthetic fuels.

E-fuel production has the potential to be a sustainable practice by offsetting emissions through recapturing atmospheric carbon dioxide during production. This process means that burning e-fuels results in close to net-zero emissions, which is increasingly important for a contemporary society transitioning away from fossil fuels and with greater concern for environmental preservation.

How Are E-Fuels Produced?

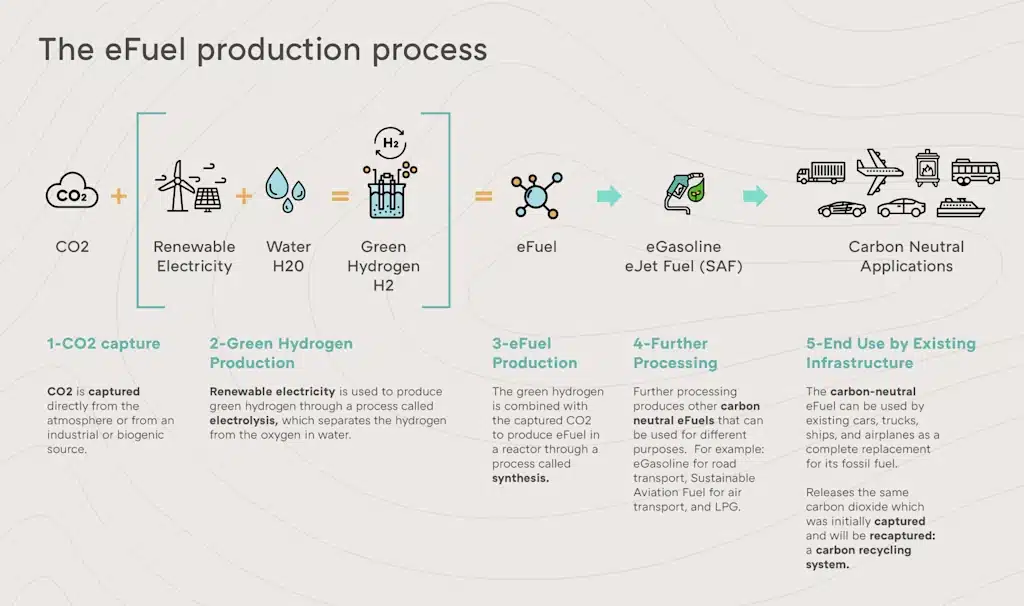

The e-fuel production process starts with recapturing carbon dioxide using various techniques to obtain CO2 directly from the atmosphere, or from alternative sources within the environment.

A second renewable electricity source, such as solar power or hydroelectricity is used to produce hydrogen through a sustainable technique called electrolysis. The electrolysis process occurs when an electric current is used to separate hydrogen atoms from oxygen in water.

Following this process, the hydrogen is combined with the captured carbon dioxide in a plant through a process called synthesis. This process produces e-fuel typically in the form of methanol.

In certain cases, methanol can be capable of being used to power vehicles directly or can be refined and converted further. Major oil company ExxonMobil has invented a conversion process for methanol-to-gasoline, which can be used as a substitute for naturally sourced fossil fuels including petrol and diesel.

Benefits of E-Fuels

E-fuels provide wide ranging benefits to both the environment as well as everyday consumers.

Environmental

The key benefit of e-fuels is the fact that the carbon footprint is substantially reduced when compared to conventional, naturally sourced fossil fuels. Car manufacturer Porsche indicates through their research that the reduction in carbon dioxide emissions could be up to approximately 85%.

E-fuels also allow the potential of wind and solar power to be fulfilled globally due to the production process where renewable electricity, atmospheric carbon dioxide and hydrogen from water are all utilised.

Although burning e-fuels still releases carbon dioxide in a similar fashion to fossil fuels, synthetic fuels burn far cleaner. Fossil fuels generally range between 30 and 40 components in their make-up, while synthetic fuels have as little as eight. E-fuels also emit significantly less particulate matter and nitrogen oxide.

E-fuels have the ability to be stored easily and transported over long distances without energy loss. This helps to solve a central issue of the transition to clean energy, which is the inability to have renewable energy permanently available and fed into the energy grid. Synthetic fuels also pose no disposal or recycling issues that are common with conventional fossil fuels.

Compatibility

In theory, synthetic e-fuels can be refined to mirror the properties of the diesel and petrol available today.

This will allow existing petrol station infrastructure and tankers to continue being used, saving costs substantially. This also helps to service developing countries and markets that do not have the capacity to roll out costly electric vehicle charging networks.

Due to the compatibility of e-fuels with internal combustion engines and efficient condensing boilers, synthetic fuels can be successfully deployed for use in approximately 1.3 billion vehicles globally, as well as being compatible with heating systems that run on liquid fuels.

Versatility

The versatility of e-fuels is also a major benefit as they are suitable for all modes of transport. This includes passenger and heavy-duty vehicles, ships, and airplanes. Synthetic fuels also have the capability to be used as a substitute for crude oil within the chemical industry.

At present, there is no reasonable technological alternative to using synthetic fuels within the aviation, shipping, construction, agriculture, forestry, and large segments of the heavy goods traffic sectors.

Drawbacks & Limitations of E-Fuels

While the benefits of eFuels are extensive, there are some limitations to be aware of.

Emerging Technology

Although the scientific principles behind e-fuels are well understood, carbon capture and synthesis technologies are at an emerging stage of development and these processes require comparatively large amounts of energy to be performed.

Renewable Viability

Ensuring that renewable energy is used exclusively to power the electrolysis process remains a challenge. This can result in restrictions on location or lead to a higher cost for the synthetic fuel end product.

Potential Cost

Porsche notes that once production has increased and economies of scale are achieved, the target wholesale price of e-fuel would be around $2 USD/litre. This price remains considerably more expensive than the 98-octane premium unleaded on the market today and would be subject to various government taxes and levies. Porsche have also indicated that there is a high chance that e-fuels will be available in various octane ratings commercially. Similar to premium unleaded when compared with the standard version, high octane types of e-fuel would carry a greater cost for consumers.

Australia’s Significant Contribution

Australia will become a significant contributor to the production of global e-fuels with Porsche and its partners planning to produce approximately 100 million litres annually in Tasmania from 2026.

HIF Global LLC, in which Porsche bought a 12.5% stake in early 2022, plan to build its carbon neutral e-fuel plant approximately 30km south of Burnie, Tasmania and will take design inspiration from a similar plant operating in Chile.

Porsche announced the plans to build an Australian facility in April 2022 and have now locked in the HIF (Highly Innovative Fuels) Tasmania Carbon Neutral E-Fuel Plant as the first commercial scale facility to be built down under.

The facility is expected to have a 40-year operational life and promises to use renewables to produce green hydrogen. The 250-megawatt site has production projections exceeding 100 million litres annually and will have the ability to create up to approximately 190 tonnes daily.

Porsche estimates that the switch to e-fuels will result in a drop of carbon dioxide emissions by roughly 260,000 tonnes annually. This reduction will allow internal combustion engines to continue being utilised in the face of emission nets tightening globally.